Our Customers

Customers around the world

How McMaster and NRG joined forces to guarantee the delivery of medical isotope iodine-125

How EDF in the UK achieved more than 40 years of lifetime extension with NRG

How Vattenfall saved €500,000 per cycle with NRG's fuel management software

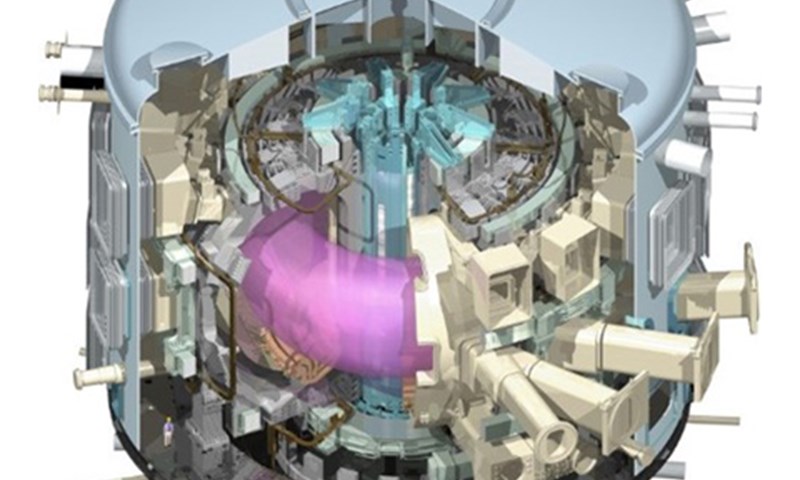

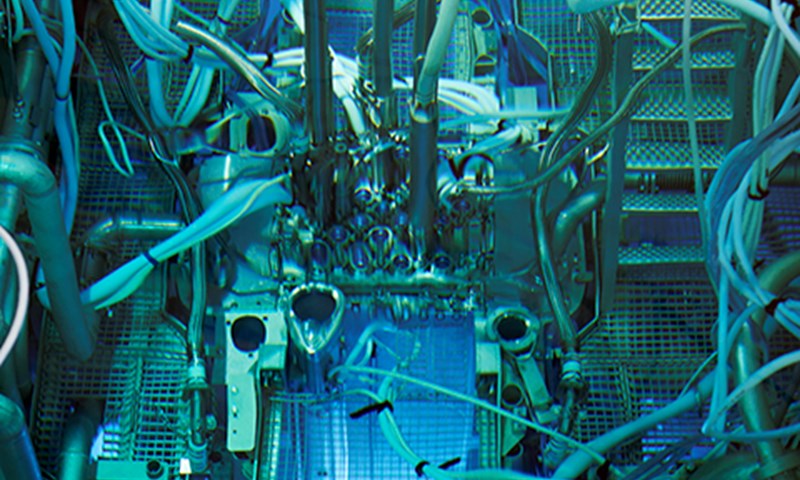

How NRG completed the qualification of the first wall panels of ITER

A few of our success stories

In 2017, there was suddenly a worldwide shortage of iodine-125, used for brachytherapy for prostate cancer, because one of the large producers was temporarily shut down. McMaster & NRG joined forces for global supply.

High Temperature Reactors are known for their high efficiency due to the high temperature and for being 'inherently safe’. Meaning that they can never have a core meltdown. The most important reason for this safety performance? The unique fuel that is used. Learn how NRG helped the Chinese Tsinghua University with their fuels.

In 2016 NRG concluded the first part on the Qualification of the ITER First Wall Assemblies, the second part is conducted at the premises of project partner Forsungzentrum Juelich in 2018.

How we reduced operating costs for Vattenfall with €500,000 per cycle.

In 2015 NRG started together with the European Joint Research Centre (JRC) in Karlsruhe a series of nuclear fuel irradiation experiments to support the development of Molten Salt Reactor technology.

Fuel creep irradiations for Advanced Gas-Cooled Reactors: How the BLACKSTONE programme realised more than 40 years lifetime extension for EDF.