McMaster & NRG

A unique collaboration between McMaster & NRG

26 August 2020

Chris Heysel

Director of Nuclear Operations and Facilities at McMaster University

Committed to creating a brighter world

Chris Heysel has worked for McMaster University for 19 years, where he is responsible for all of the university's nuclear facilities. These facilities form an isotope manufacturing facility that produces, processes and separates McMaster bulk radioisotopes, which are sold to major pharmaceutical and industrial companies.

- The McMaster Nuclear Reactor

- 5 MW research and isotope-production reactor

- 3 accelerators

- Cyclotron isotope production and research facility

About the collaboration between McMaster & NRG

A unique collaboration in the field of nuclear medicine has been set up between the Netherlands and Canada, as Nuclear Research & consultancy Group (NRG) and McMaster University have teamed up to advance customer service to a new level. Together, we will provide the world with the highest quality radioiodine (iodine-125), used for the treatment of prostate and other various types of cancers, at the highest level of reliability.

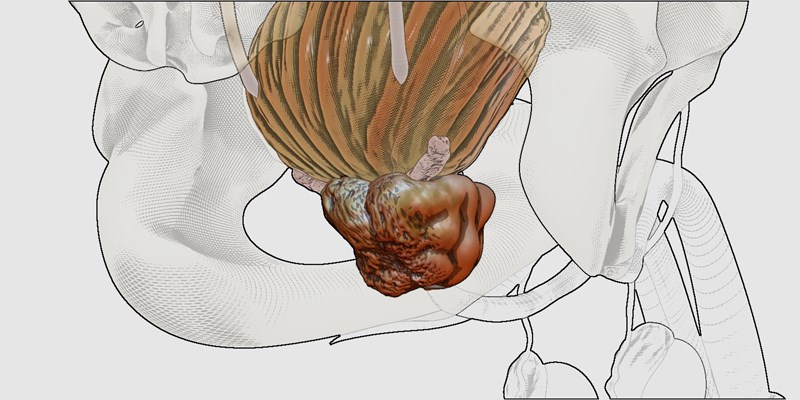

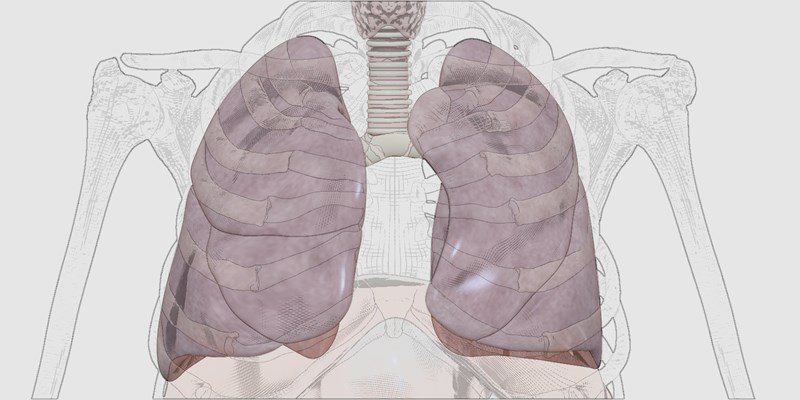

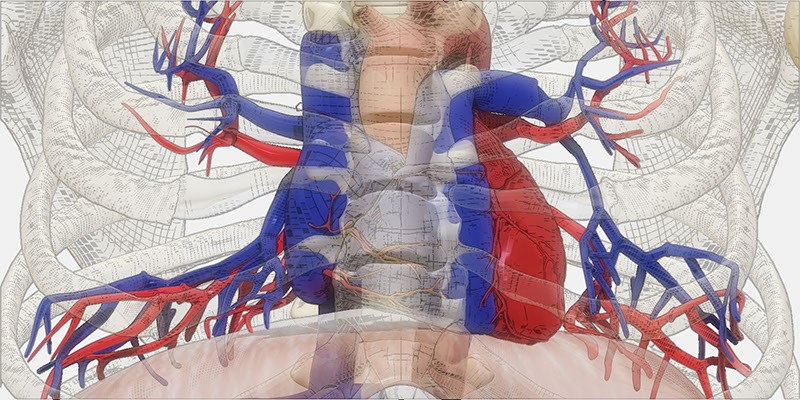

Brachytherapy

Brachytherapy is a procedure that involves placing radioactive material inside the human body. Brachytherapy with iodine-125, a radioactive isotope, is an established treatment and yields good results for patients with several cancers such as prostate cancer.

Motivation

Access to iodine-125 was in great danger in 2017 as one of the 3 iodine-125 producing reactors unexpectedly shut down. A worldwide shortage of the product occurred. As a result, many patients would not receive optimal critical treatment. This situation required an acute and sustainable emergency solution. The Netherlands and Canada responded to this global shortage with a new collaboration.

Together, NRG and McMaster ensure a reliable supply of high-quality iodine-125.

The strategic geographic locations of the Netherlands and Canada enable efficient transportation worldwide. We can guarantee the availability of this product all over the world.

The manufacturing process

To produce the desired iodine-125, pure xenon gas is irradiated. This adds a neutron to the stable isotope xenon-124, which turns it into xenon-125. As this is an unstable isotope, it will quickly decay into iodine-125. NRG ships this material to Canada, where the team at McMaster harvest the iodine-125 and then process and qualify it, before it is supplied to customers worldwide. The iodine-125 solution is incorporated in tiny seeds the size of a grain of rice. Physicians will take those radioactive seeds and implant them around a tumour.

Conclusion

We believe every patient should have access to proven treatments such as brachytherapy with iodine-125 seed implants. By teaming up with McMaster University, world’s leading supplier of iodine-125, we ensure a reliable supply of iodine-125, 365 days a year.

Dual supply brings not only high quality standards, but also reliability and continuity.