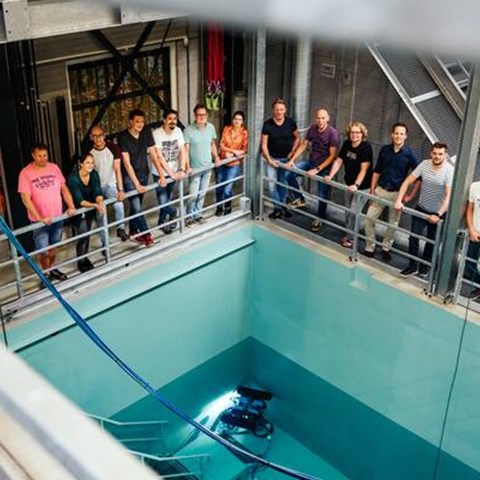

Inspection Services

- Innovative, automated testing

- Research and test facility

- Independent, objective results

Automated and efficient Non-Destructive Testing, tailor-made for your situation. The Inspection & Services team helps you perform Non-Destructive Testing (NDT).

Non-Destructive Testing

Are you looking for a Non-Destructive Testing or Inspection partner? The Inspection & Services team from NRG has years of experience performing inspections on reactor components. We enable you to operate optimally, safely and reliably.

How do we perform Non-Destructive Testing?

Highly radioactive and contaminated components are hard to access for human personnel. Therefore we develope special tooling, combining inspection equipment and robotics. The resulting remotely controlled inspection is performed on site, in a quick, efficient and responsible manner. The types of inspections we perform are:

- Ultrasonic inspection

- Eddy Current inspection

- Visual inspection

NRG is your partner for Non-Destructive Testing. We are especially proficient in performing regular inspections, or inspecting difficult to reach components in your facility. Contact us for the possibilities!

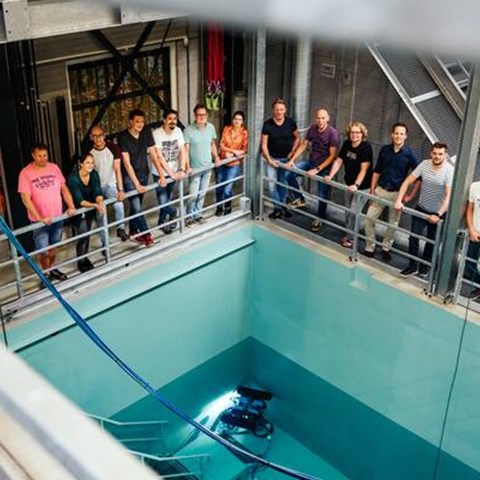

Ultrasonic and Eddy Current inspection of weld in reactor vessel

Highly radioactive and contaminated components are hard to access for human personnel. Therefore we develope special tooling, combining inspection equipment and robotics. The resulting remotely controlled inspection is performed on site, in a quick, efficient and responsible manner. The types of inspections we perform are:

- Ultrasonic inspection

- Eddy Current inspection

- Visual inspection

NRG is your partner for Non-Destructive Testing. We are especially proficient in performing regular inspections, or inspecting difficult to reach components in your facility. Contact us for the possibilities!

Visual inspection of reactor vessel

Meticulously we mapped and assessed a reactor vessel, centimetre by centimetre. We use our tailor-made software to increase the quality of visual inspections. The camera maps the location of the images.

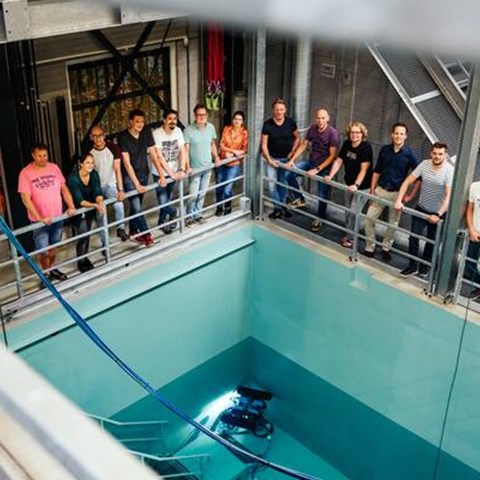

Ultrasonic inspection of bolts

Highly radioactive and contaminated components are hard to access for human personnel. Therefore we develope special tooling, combining inspection equipment and robotics. The resulting remotely controlled inspection is performed on site, in a quick, efficient and responsible manner. The types of inspections we perform are:

- Ultrasonic inspection

- Eddy Current inspection

- Visual inspection

NRG is your partner for Non-Destructive Testing. We are especially proficient in performing regular inspections, or inspecting difficult to reach components in your facility. Contact us for the possibilities!

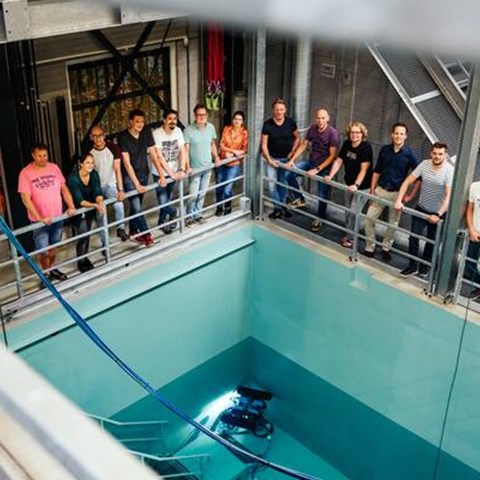

Eddy Current inspection

Highly radioactive and contaminated components are hard to access for human personnel. Therefore we develope special tooling, combining inspection equipment and robotics. The resulting remotely controlled inspection is performed on site, in a quick, efficient and responsible manner. The types of inspections we perform are:

- Ultrasonic inspection

- Eddy Current inspection

- Visual inspection

NRG is your partner for Non-Destructive Testing. We are especially proficient in performing regular inspections, or inspecting difficult to reach components in your facility. Contact us for the possibilities!

Visual inspection of fuel elements

For the purpose of inspecting fuel elements, our Inspection & Services team has developed an inspection tool, that can photograph and measure objects without coming into contact with them. Despite the required distance, the device measures with a precision of 100µm. A software package had been developed to automatically perform profile analyses.

Want to know more?

Contact

Martin Bakker

Manager Inspection & Services

M. m.bakker@nrg.eu