Irradiation Services

- One-stop-shop for irradiation services

- 60 years of experience

- High quality, reliable data

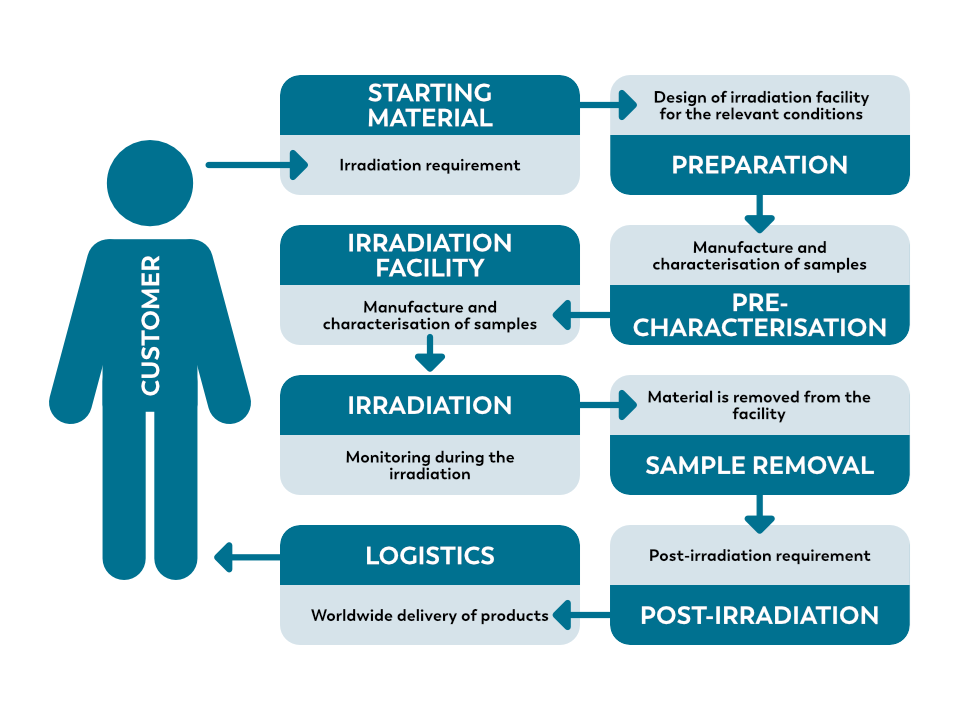

Would you like to know how your material behaves in a nuclear reactor? We predict the lifetime behavior of materials in radioactive environments.

About Irradiation Services

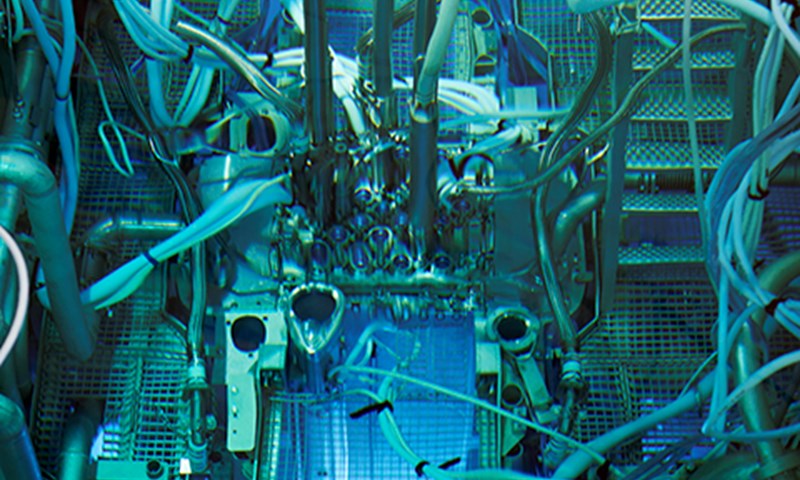

Safe and responsible nuclear energy, both for existing and innovative nuclear energy systems. How do we do that? Via irradiation projects that combine the perfect mix of skilled professionals and NRG’s state-of-art infrastructure.

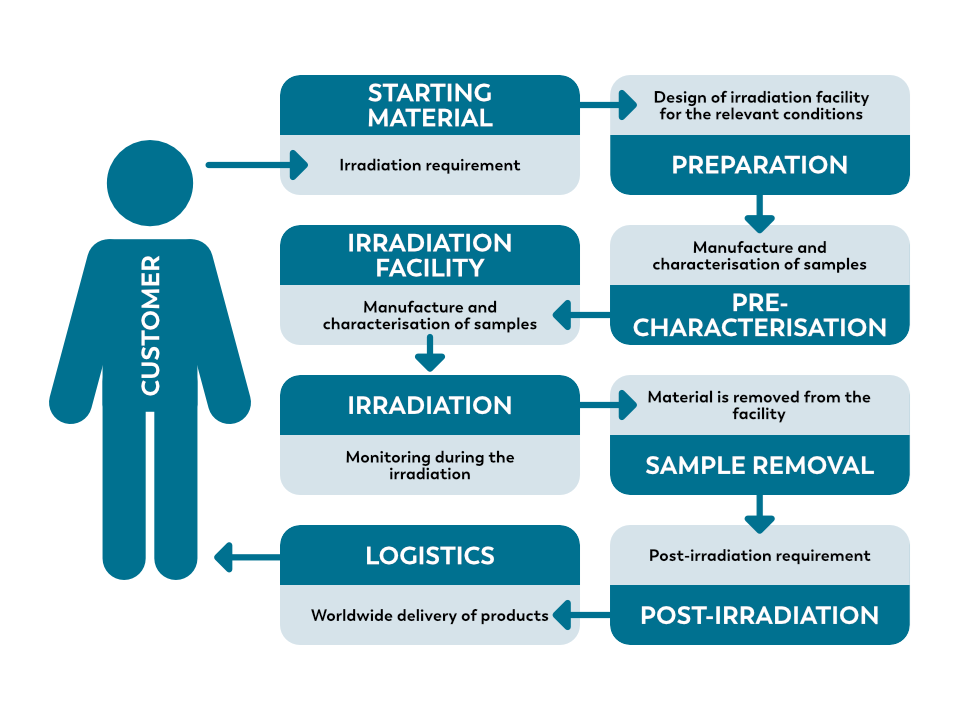

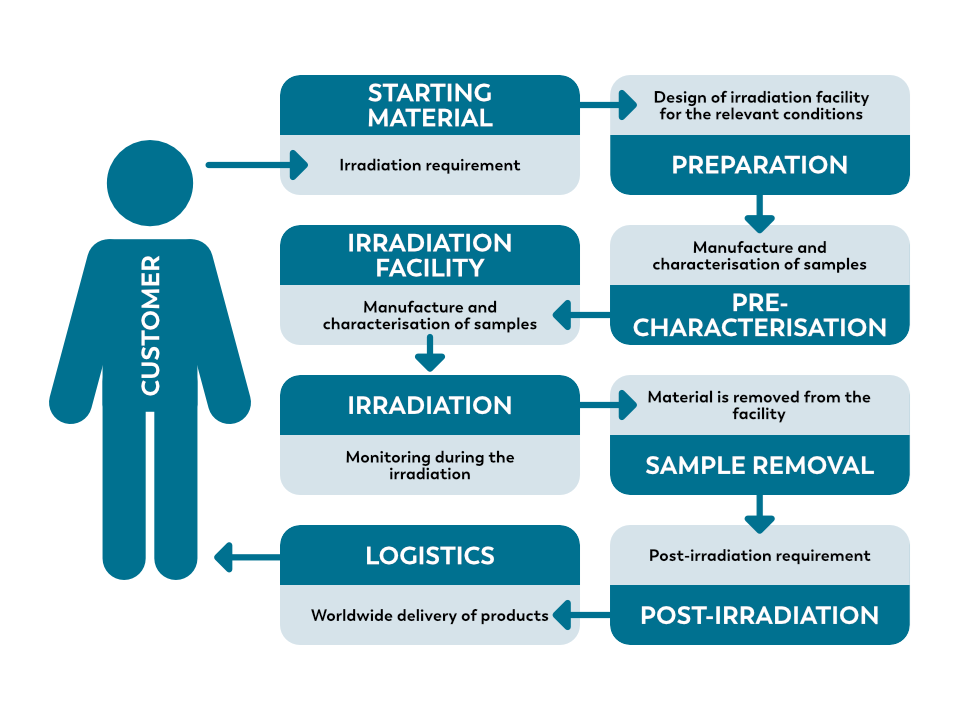

We translate your specific questions into customized irradiation projects: from conceptual design to tailored fabrication in our work-shop; from irradiation at the HFR (High Flux Reactor) to examination at our hot cell labs; from nuclear transport to storage and waste treatment.

We help you by performing accelerated tests that reveal end-of life time, speed of material degradation, qualification on new materials or fuels and much more.

Typical activities that we carry out in our daily work are:

- Manufacture and handling of fuel and materials samples in a safe and isolated environment

- Design and build irradiation facilities 100% in-house

- Irradiation under well controlled and stable conditions

- Monitoring of crucial parameters such as: gas flow, gas composition, temperature, strain, sample dimensions, etc..

Material Irradiation Services

Materials in nuclear reactors are exposed to high levels of radiation. High temperature, corrosive environment and the interaction with radiation changes the behavior of the material. This impacts the service life of the reactor, operational performance and safety

We asses and describe material behavior under accelerated irradiation conditions. Hereby, we take a look into the future and predict their behavior in real use.

Read more

Fuel Irradiation Services

Safe and responsible nuclear energy, both for existing and innovative nuclear energy systems. How do we do that? Via irradiation projects that combine the perfect mix of skilled professionals and NRG’s state-of-art infrastructure.

We translate your specific questions into customized irradiation projects: from conceptual design to tailored fabrication in our work-shop; from irradiation at the HFR (High Flux Reactor) to examination at our hot cell labs; from nuclear transport to storage and waste treatment.

We help you by performing accelerated tests that reveal end-of life time, speed of material degradation, qualification on new materials or fuels and much more.

Typical activities that we carry out in our daily work are:

Read more

Molten Salt Reactor Irradiation Services

Safe and responsible nuclear energy, both for existing and innovative nuclear energy systems. How do we do that? Via irradiation projects that combine the perfect mix of skilled professionals and NRG’s state-of-art infrastructure.

We translate your specific questions into customized irradiation projects: from conceptual design to tailored fabrication in our work-shop; from irradiation at the HFR (High Flux Reactor) to examination at our hot cell labs; from nuclear transport to storage and waste treatment.

We help you by performing accelerated tests that reveal end-of life time, speed of material degradation, qualification on new materials or fuels and much more.

Typical activities that we carry out in our daily work are:

Read more

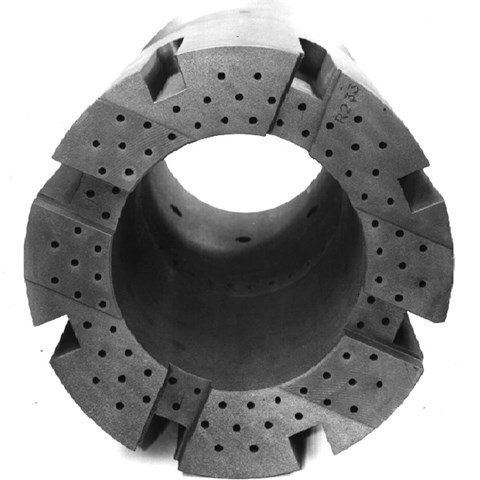

Fuel Creep: an introduction

Creep is the deformation of fuel under stress and is an important parameter for nuclear fuel. It helps in reducing stresses on the cladding of fuel in power reactors. NRG has developed a new technique to measure fuel creep at high temperatures with very high accuracy.

A few of our success stories

Fuel creep irradiations for Advanced Gas-Cooled Reactors: How the BLACKSTONE programme realised more than 40 years lifetime extension for EDF.

High Temperature Reactors are known for their high efficiency due to the high temperature and for being 'inherently safe’. Meaning that they can never have a core meltdown. The most important reason for this safety performance? The unique fuel that is used. Learn how NRG helped the Chinese Tsinghua University with their fuels.

In 2015 NRG started together with the European Joint Research Centre (JRC) in Karlsruhe a series of nuclear fuel irradiation experiments to support the development of Molten Salt Reactor technology.

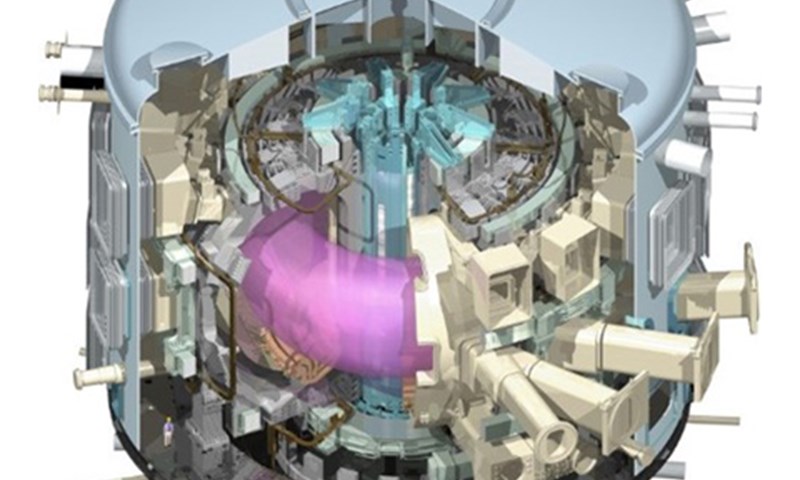

In 2016 NRG concluded the first part on the Qualification of the ITER First Wall Assemblies, the second part is conducted at the premises of project partner Forsungzentrum Juelich in 2018.

Our customers and partners are worldwide

More information?

We are happy to tell you more

Arjan Vreeling

Manager R&D Nuclear Fuels & Materials

T. +31 6 23284321

M. vreeling@nrg.eu