Fuel Creep

Fuel Creep: an introduction

Fuel Creep is the slow deformation of a solid under stress. It is an important parameter to understand the behavior or nuclear fuel. It helps in reducing stresses on the cladding of fuel in power reactors. NRG has developed a solution to measure with very high accuracy the creep of nuclear fuels under in-use conditions.

Fuel Rod assembly

The fuel in a light water reactor is made from uranium oxide, sometimes also plutonium is added. This oxide in pressed into pellet, and placed in 4 meter long Zircaloy tubes called the cladding which are packed together in a grid which forms a final Fuel assembly.

A nuclear reactor core is made from a few hundred of these fuel assemblies, and when the reactor is turned on the uranium in the fuel pellets starts to fission and heat is produced.

Why measure creep?

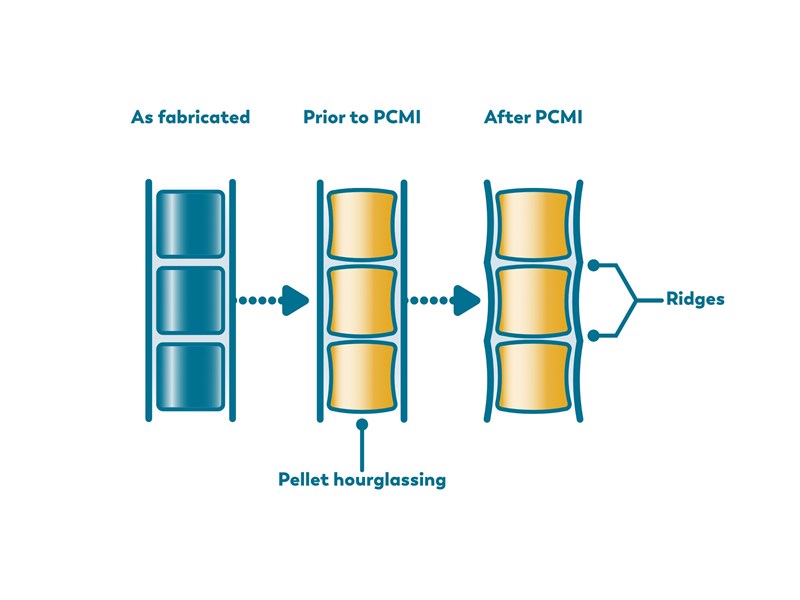

The creep behavior plays an important role in the safety evaluation of a nuclear fuel. The force that the fuel pellets exert on the cladding that contains the fuel can be influenced by the creep of the fuel. If this value is unknown or has a high uncertainty, large safety margins must be applied to guarantee safe operation leading to low efficiency and over-specification.

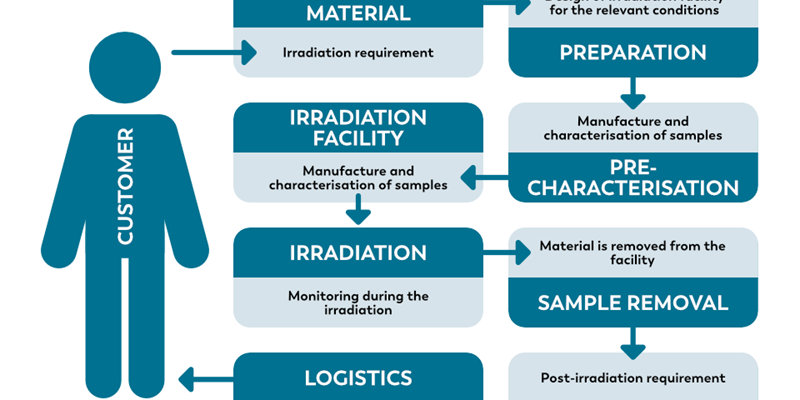

In the development of new fuels or claddings it is also an important factor to find the best combination of different materials. The irradiation capsule at NRG can measure creep during irradiation of all types of fuel with very high accuracy.

Read More

Interested?

Contact our irradiation experts

Team irradiations

Design challenges

The amount of creep depends on both the temperature, the force that is applied on the material and the time it is irradiated. To obtain good data all these parameters must be very well known.

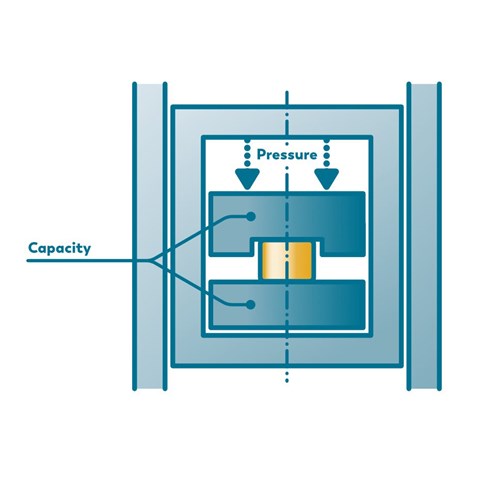

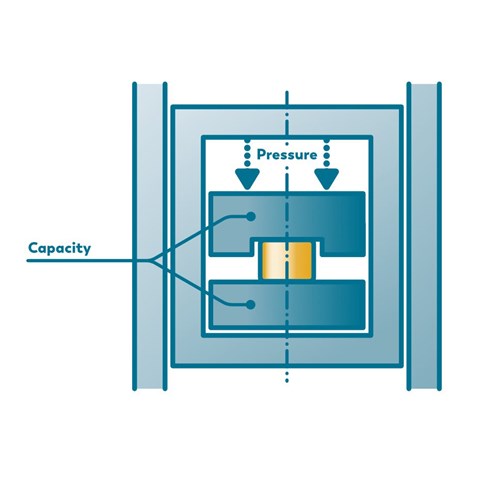

Due to the high powers the temperature gradient in a single fuel pellet can be over 1000 ºC. If creep is then measured, there is a high uncertainty of the creep rate at a certain temperature. To minimize the temperature gradient, the samples must remain very small. Small samples however mean than there are very small dimensional changes which are difficult to measure. The capacitance between two plates is very sensitive

An innovative technique

The amount of creep depends on both the temperature, the force that is applied on the material and the time it is irradiated. To obtain good data all these parameters must be very well known.

Due to the high powers the temperature gradient in a single fuel pellet can be over 1000 ºC. If creep is then measured, there is a high uncertainty of the creep rate at a certain temperature. To minimize the temperature gradient, the samples must remain very small. Small samples however mean than there are very small dimensional changes which are difficult to measure. The capacitance between two plates is very sensitive

More information?