Molten Salt Reactor FAQ

1. What is a Thorium Molten Salt Reactor?

A Thorium Molten Salt Reactor is a Molten Salt Reactor (questions 2-3) running on Thorium fuel (questions 4-6).

2. What is a Molten Salt Reactor?

Molten Salt Reactors (MSRs) are nuclear power plants (NPPs). Nuclear power plants exist to produce (a lot of) electricity in a predictable and reliable way, without causing CO2 emissions while taking up little space. The combination of these qualities make them very useful additions to ‘wind’ and ‘solar’ in the goal of creating a CO2 neutral world.

MSRs are developed to improve on existing nuclear power plants. MSRs can make nuclear energy cheaper and cleaner, and they will be used in ways that ordinary reactors cannot be used, for instance to supply heat directly to industries (like the chemical or steel industry, or even the fabrication of solar cells).

In the 1960s a small experimental MSR was operated for five years at the Oak Ridge National Laboratory in the US. This (and the related research) has produced a lot of useful knowledge and operating experience. Nevertheless, that experiment was a pilot developed to prove a concept, not a full scale reactor.

Today much more in-depth knowledge and data are needed to allow for a first start-up of an MSR; on the other hand new technologies offer new possibilities. NRG, other research institutes and start-up companies around the world put time and effort in the development of molten salt technology for clean energy.

3. How do Molten Salt Reactors (MSRs) work?

To understand molten salt reactors, we first need to know how ordinary nuclear power plants (NPPs) produce electricity. Existing NPPs typically use solid pellets of enriched uranium (oxide) as the fuel, of about 1 cm in diameter and 1 cm in height. These pellets are packaged in sealed metallic tubes (claddings). A lot of heat is produced in the uranium pellets by the splitting of uranium or plutonium atoms into smaller fragments (see also questions 5 and 6). This heat is converted into electricity. The process of generating electricity from heat is very similar to that happening in coal or gas plants, which use the heat produced from burning the coal or gas. In both cases, water under pressure is heated to the boiling point, as in a pressure cooker. The water is converted to steam, and the steam then drives a turbine. The movement of the turbine is then converted to electricity.

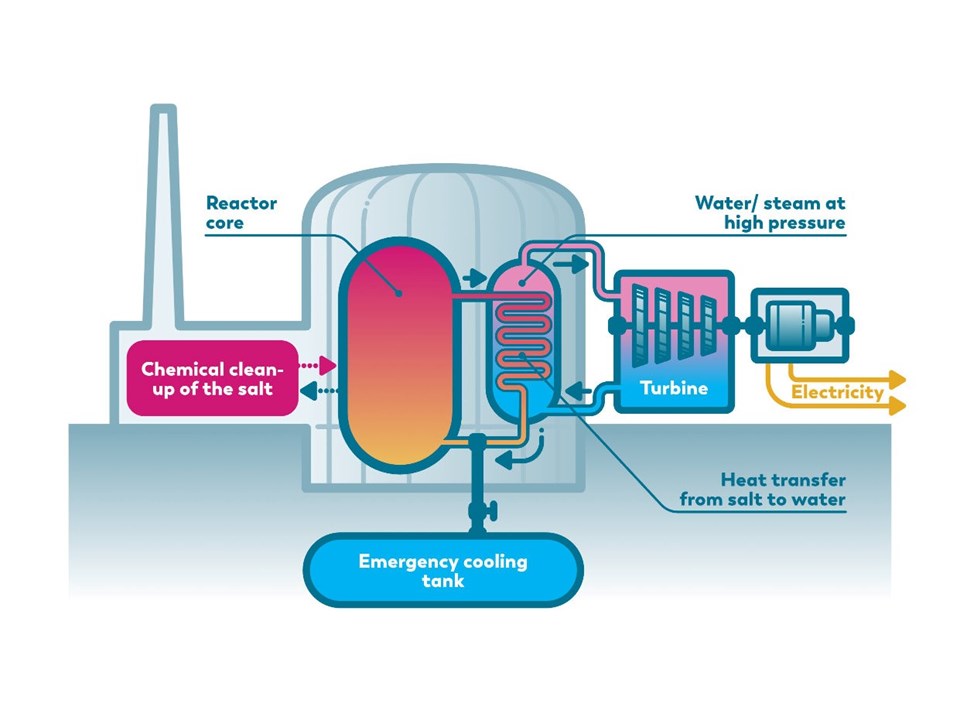

A molten salt reactor also converts heat to electricity, but in this case the fuel does not come in the form of pellets. Instead, the fuel is dissolved into a liquid salt mixture, at high temperature (450-750 oC). The energy from the splitting of uranium atoms is used to directly heat up the molten salt. The hot salt is then used to boil water for electricity, or to deliver the heat to nearby industrial processes. Immediate benefits of this is a higher efficiency of electricity production (because the efficiency scales with temperature). Besides this the reactor is operated at much lower pressure then NPPs which improves safety and reduces costs.

4. What is a thorium reactor?

Uranium (U) is the default fuel for nuclear reactors worldwide, and plutonium (Pu) is used in some. Thorium (Th) is a useful alternative: there is about 4 times more thorium in the earth’s crust compared to uranium and Thorium fuel produces less long-living waste compared to U and Pu based fuels.

5. How does thorium compare to uranium?

See question 4.

6. How do thorium reactors work?

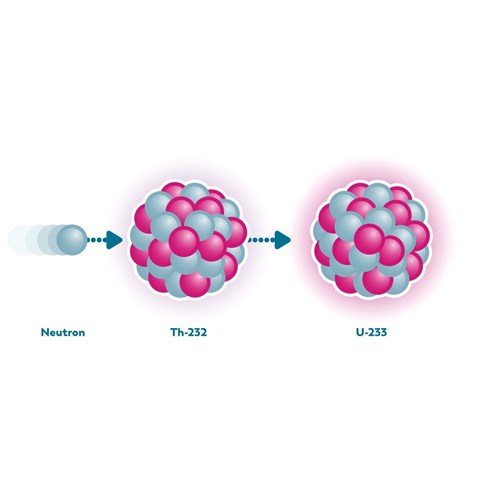

The above comparison between uranium and thorium gives only part of the story. To extract energy from thorium, it first needs to be converted to a ‘light’ version of uranium by bombarding the material with neutrons. Fortunately, this happens naturally in a running nuclear reactor. The creation of new fuel (breeding) and the generation of energy (burning) for electricity both use the same neutrons. One of the biggest challenges is to achieve the right balance between ‘fuel breeding’ and ‘fuel burning’. But if you manage to make it work, you will need very little thorium to produce a lot of clean energy.

Currently we are throwing away more than 90% of the uranium as waste without extracting energy from it. We will not be running out of uranium in this century, and as long as uranium prices are low to medium, thorium reactors will not be able to compete. But in the long run, and to reduce the amount of long-living waste that will end up in underground storage facilities, we should try to do one of two things: extract much more energy from the uranium that we have in so-called ‘fast breeder reactors’; or move to thorium breeders.

Technical details

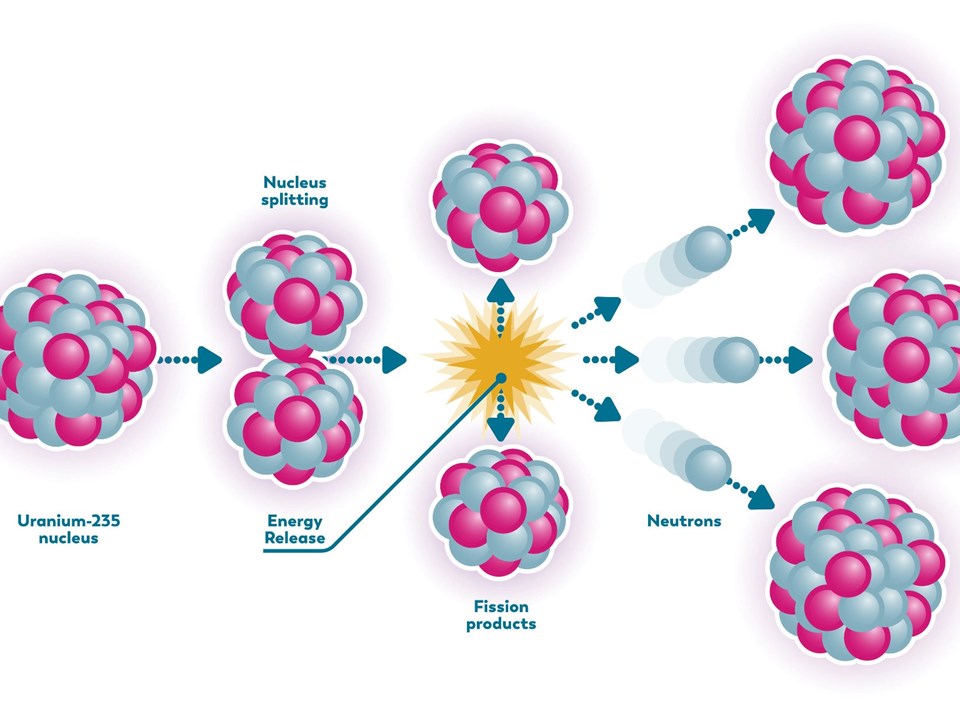

In nature, uranium (U) comes in two variants: 235U and 238U. Of these two, only 235U can directly produce energy. Energy is produced when you hit the 235U with a neutron and it splits into two pieces plus 2 or 3 new neutrons, a process called fission. In the reactor, one of these 2-3 neutrons should hit another 235U to keep the fission chain going.

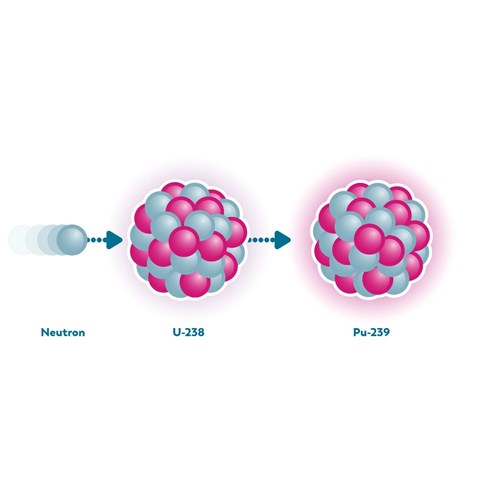

When a neutron hits 238U, it does not break into pieces and does not produce fission energy. Instead, the neutron is absorbed and plutonium (239Pu) is formed. In a typical reactor, most energy comes from 235U and a little bit extra from the generated 239Pu, which behaves much in the same way.

7. What is the ‘Lifter’ (LFTR)?

The ‘lifter’ (LFTR or Liquid Fluoride Thorium Reactor) is a particular design of a thorium molten salt reactor by the company Flibe Energy that would take full benefit from the advantages of thorium. The starting point for this design was the Molten Salt Breeder Reactor (MSBR) design developed by the Oak Ridge National Laboratory in the US in the 1960s and 1970s.

8. Can a (thorium) molten salt reactor meltdown?

A meltdown in a regular reactor is the partial melting of the core and structural materials due to overheating. In an MSR the core of the reactor is already molten (by design). Of course an MSR also has supporting structures. The changes of these structural materials melting can be ruled out for most severe accident conditions

9. Are (thorium) molten salt reactors safe?

The short answer is: any specific MSR design will go through a long series of rigorous reviews and tests, ensuring that the end product is safe.

It is however easier to answer the question: which things make that MSRs will be safer than current reactors? This is done under question 11 on the advantages of MSRs.

10. Is the (thorium) molten salt reactor possible?

Definitely. One was already built and operated last century (see question 2), and a lot of research has since been done revealing no show-stoppers. Most issues that are currently being researched fall in the category of ‘doable engineering challenges’. For instance an interesting and less straightforward challenge is how to do the book-keeping of nuclear fuel going into and out of the reactor when that fuel forms a big pool of molten salt.

11. Why a Molten Salt Reactor?

Partial answers were already given in previous questions, but let’s try to sum up the benefits of MSRs:

Higher temperature

A higher temperature compared to existing nuclear power plants means higher efficiency of electricity production, and the possibility to deliver heat to industries (for instance the chemical or metal producing industries, or even solar cell producers)

Low pressure

Low pressure in the reactor means that in case of a severe accident the driving force for the spread of radioactivity is low.

Negative feedback loop

An inherent property of the molten fuel salt is that it expands when it is heated. In case the fuel becomes overheated this expansion drives some of the fuel out of the reactor. With less fuel now in the reactor, fewer uranium atoms are split and less energy produced, and the reactor cools down again. This is a very nice example of a negative feedback loop, stabilizing MSRs.

Liquid fuel

The use of a liquid fuel also has the following advantages:

- In case of emergency, the nuclear fuel can automatically be drained from the reactor core, into tanks below the reactor that can be cooled. This whole system can be made to work without human intervention, based only on the laws of physics (gravity, and the melting of a frozen plug that prevents the draining as long as the reactor runs normally)

- The fission products, the fragments produced by splitting uranium that are a major part of nuclear waste, may be removed from the fuel salt using chemical processes (Q15). This ‘salt clean-up’ has a few advantages: much less radio-activity in the reactor itself (of course this radioactivity IS then present in the neighboring building), the resulting waste can be treated more efficient, and finally the fission products do not absorb the neutrons needed for breeding and burning fuel (Q6).

15. Do (thorium) molten salt reactors produce radioactive waste?

Definitely, this is unavoidable.

Waste from nuclear fuel comes in two categories. The first category, the fission products are formed by the fragments created by the splitting of uranium atoms. The amount of fission products is simply proportional to the energy produced from fission, so any nuclear (fission) reactor will produce them in equal amounts (neglecting differences in the efficiency of converting heat to electricity, see question 3). After roughly 300 years the radio-activity of these fission products has become lower than that of the mined uranium, so at that point it is considered ‘inactive’.

The second category is that of the heavy metals uranium, plutonium, neptunium, americium and curium. The important properties of this waste category are:

- The waste is less radio-active than that from the fission products

- But it stays radio-active for a much longer period (roughly 200.000 years)

- This waste can be converted to fission products by keeping it inside a nuclear reactor until all of the heavy metal atoms have been split (by neutrons) into fission products

Ideally one would like to convert the heavy metals to fission products. The big appeal of molten salt reactors is that the liquid fuel can be chemically treated to remove the fission products, leaving the heavy metals in the reactor until they split into more fission products (Figure 1).

Imagine what you have to do in case of solid fuel: remove the fuel from the reactor, transport it to a processing facility, dissolve the pellets to remove the fission products, and then make new pellets from the remaining heavy metals, and put those back into the reactor. A lot of work, difficult and expensive. Actually, this is doable as long as you only recover the uranium and plutonium, and this is done successfully in France to reduce the amount of waste and re-use some of it.

We don’t expect the first MSRs to be able to remove the long-living heavy metal waste, but it is a real possibility further down the road.